Summary

In 2018, Eni Mexico appointed MODEC for the supply, charter, and operations of the FPSO in the Eni-operated Offshore Area 1 block in the Bay of Campeche.

Their involvement was instrumental in ensuring the successful deployment and initial operation of this groundbreaking FPSO project in the Gulf of Mexico.

FPSO Specifications

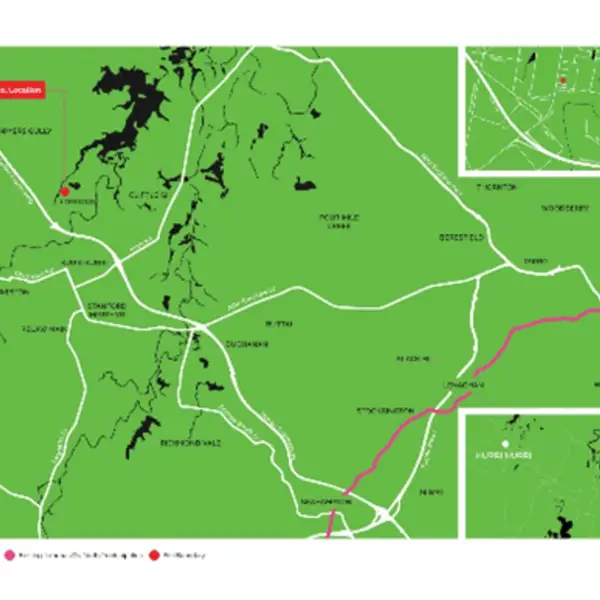

- Water Depth: Approximately 32 meters

- Distance from Coast: 10 kilometers off Mexico's coast

- Processing Capacity:

- Oil: 90,000 barrels per day

- Gas: 75 million cubic feet per day

- Water Injection: 120,000 barrels per day

- Storage Capacity: 700,000 barrels of oil

Innovative Mooring System

The FPSO features a Disconnectable Tower Yoke Mooring System (DTYMS), a first-of-its-kind design in the industry. Developed by SOFEC, Inc., a MODEC group company, this state-of-the-art system allows the FPSO to:

- Moor in shallow water

- Disconnect and depart the area to avoid winter storms and hurricanes common in the Gulf of Mexico

The mooring jacket for the DTYMS was fabricated in Altamira, Mexico.

Services Provided by C2O Americas

C2O Americas played a crucial role in various aspects of the MODEC ENI MV34 FPSO MIAMTE project. Their contributions included

Subsea Installation Client Representative:

- Acted as the client's eyes and ears during the subsea installation phase

- Ensured all subsea components were installed according to specifications and industry standards

- Provided regular reports and updates to the client on installation progress and any challenges encountere

MV34 Tower Yoke Person In Charge (PIC):

- Oversaw the installation and commissioning of the innovative Disconnectable Tower Yoke Mooring System

- Coordinated between various teams to ensure smooth integration of the DTYMS with the FPSO

- Managed risk assessments and safety protocols specific to the tower yoke operations

Hook-Up and Commissioning (HUC) Phase for Subsea and Topsides:

- Supervised the critical HUC phase for both subsea systems and topside facilities

- Coordinated testing and verification of all systems to ensure they met operational requirements

- Managed the transition from installation to operational readiness

FPSO Connection to the Tower:

- Oversaw the delicate process of connecting the FPSO to the Disconnectable Tower Yoke

- Ensured proper alignment and secure connection between the FPSO and the mooring system

- Conducted thorough checks and tests to verify the integrity of the connection

Throughout these services, C2O Americas demonstrated their expertise in:

- Project management in complex offshore environments

- Technical knowledge of FPSO systems and innovative mooring solutions

- Commitment to safety and operational excellence

- Ability to coordinate effectively with multiple stakeholders, including MODEC, Eni Mexico, and various contractors